Sobre nós

As a professional mould-maker, A-TorchMould Limited was guided by the principles of providing high quality mould and putting the customer first. These same values continue to be at the heart of ATM today.

A-TorchMould Limited widely adopted advanced engineering technology, comprehensively optimizing workflow, positive inflow technical talent. Our mold manufacturing facility has experienced continuous growth since it was established in 1998. Now, A-Torchmould Limited has developed into a company with more than 6000 square meter production plant.

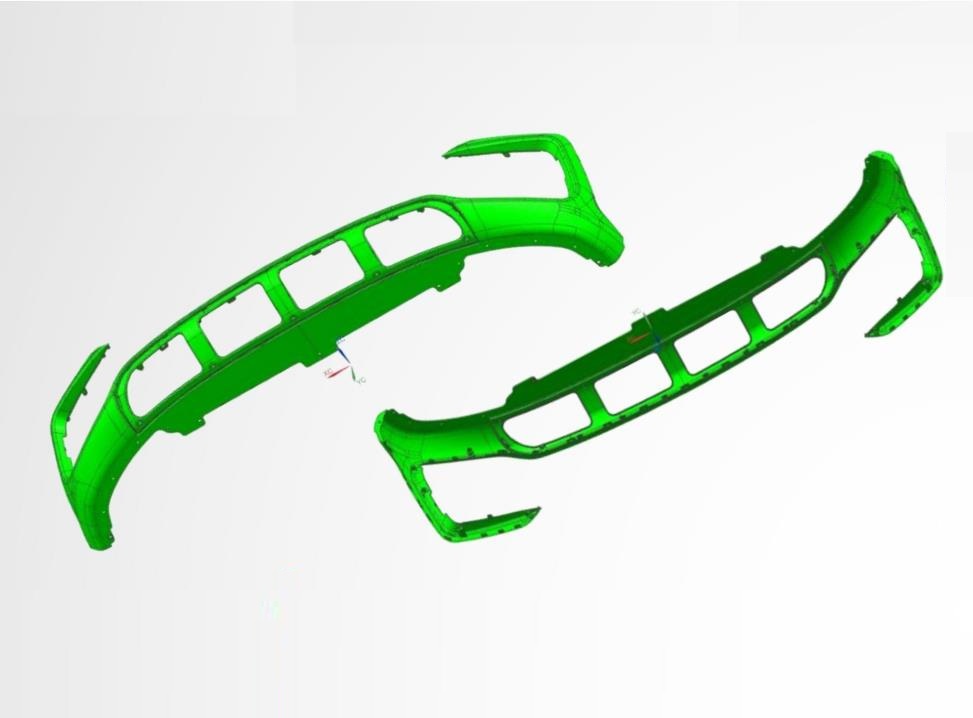

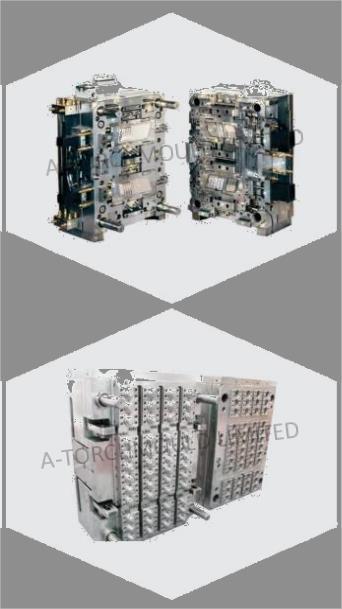

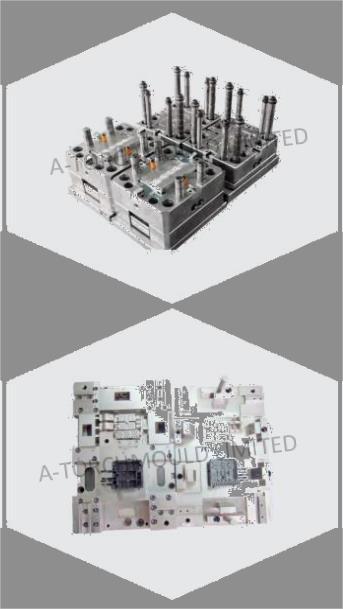

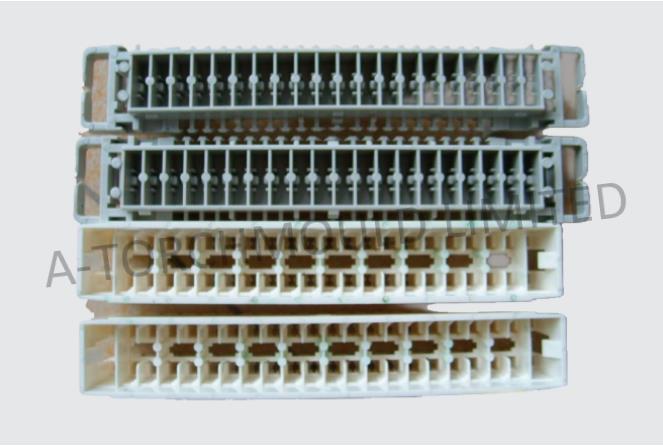

As a manufacture to a body specialized production factory, our main business fields are producing moulds and run mass production for automotive, industrial products, family appliance, computer, toy and telecommunication device, etc.

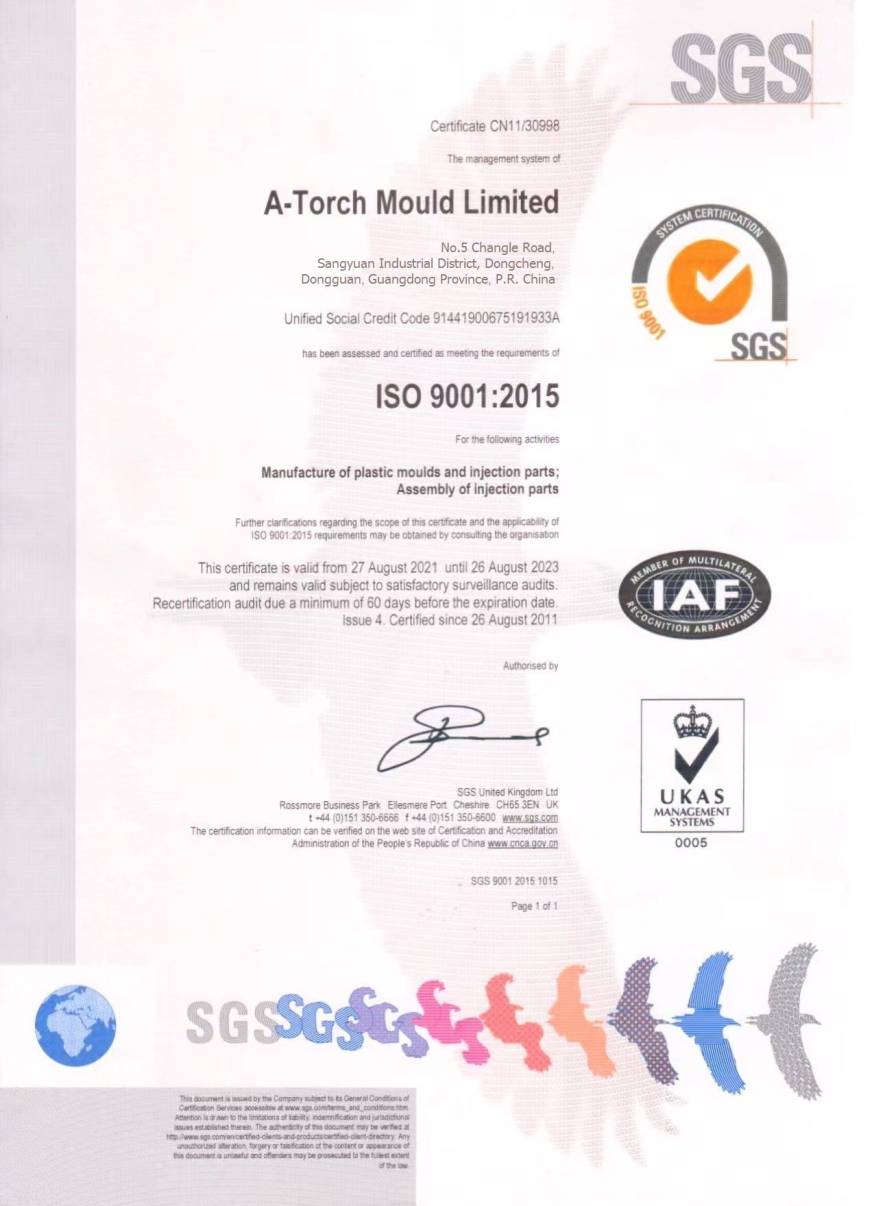

We strictly manage and regulate according to ISO9001 quality management system. Atualmente, the company has more than 20 senior engineers and more than 70 professional technicians. Years of industry experience and innovative spirit of excellence, we constantly provide excellent technology and service to custom design, engineering manufacturing of molds custom parts.

Ao mesmo tempo, we will also drive to meet the most stringent world market demands through independent research and development of new products.

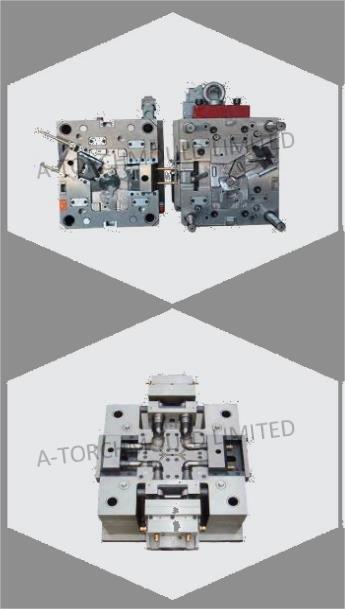

Factory Quick Review

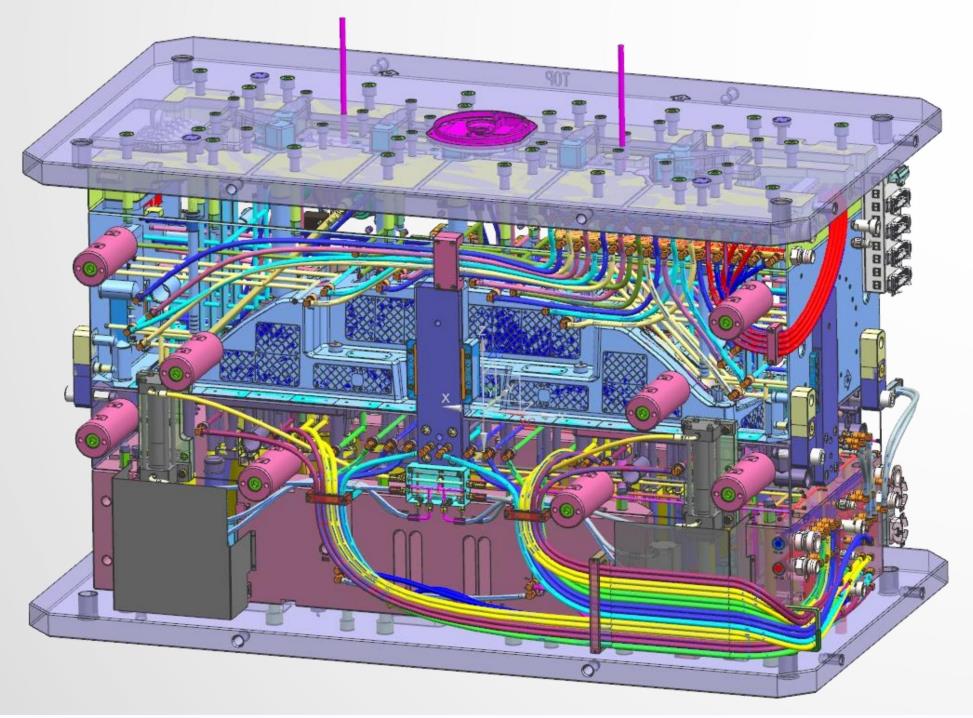

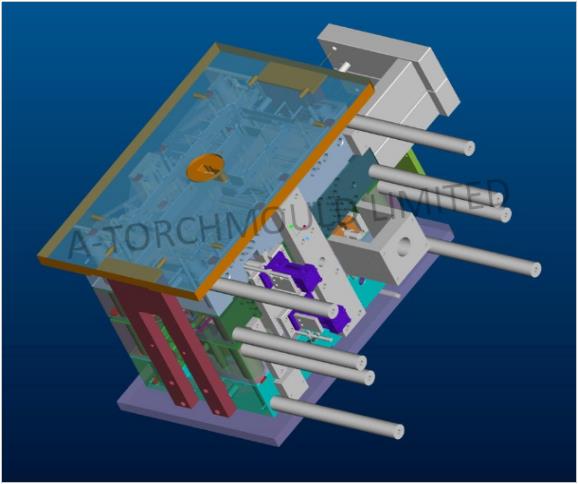

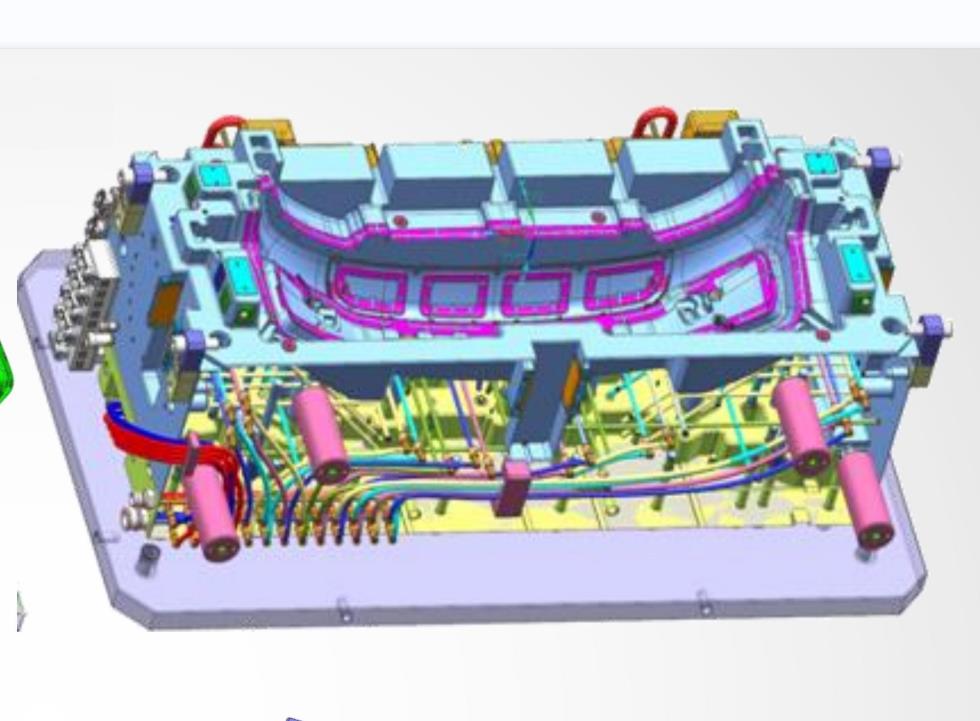

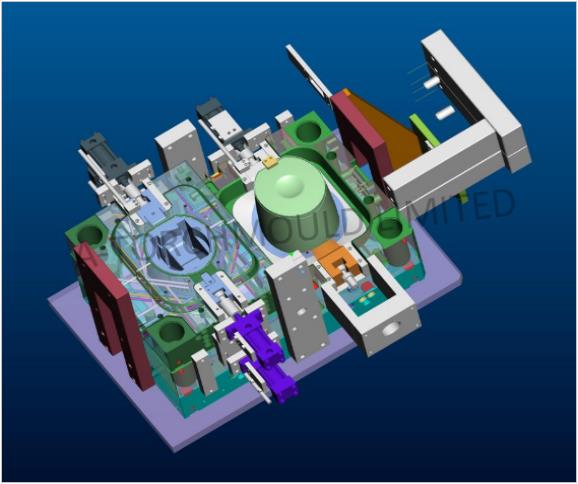

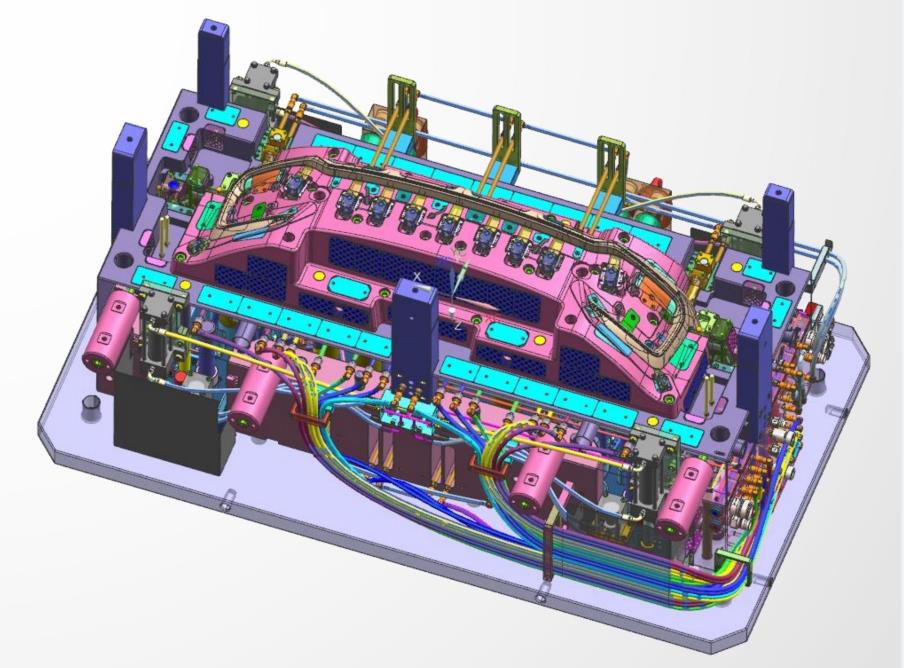

A-TorchMould Limited tem comumente usado em equipamentos de processamento de alta precisão, como centro de usinagem CNC, Usinagem de Descarga Elétrica de Corte de Arame, Grinding Machine, Fresadora, máquina injetora, etc. Formas e contornos complexos não são um problema para nossos profissionais de CNC. Usando todos os mais recentes conceitos de design de moldes, Nossos moldes são construídos com precisão e feitos para durar. Com CNC interno, EDM, e polimento, Temos total controle do processo de fabricação do molde.

The plant adhering to the ”Engineering on-site” industry guidelines.

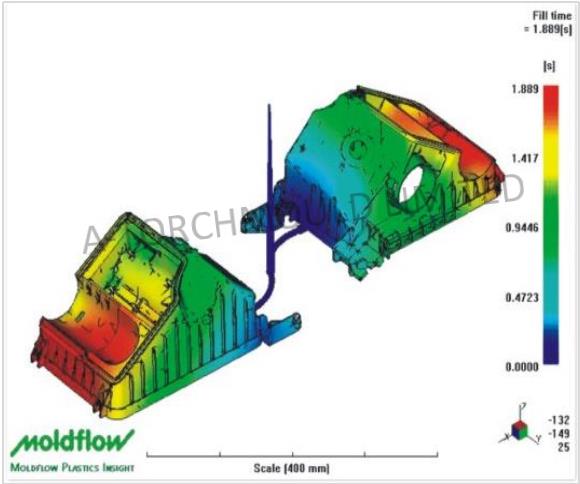

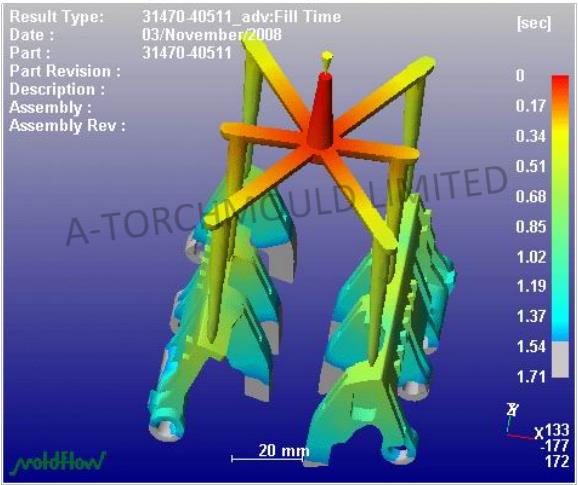

The engineering software Pro-E, SolidWorks, UG, AutoCAD, Moldflow, Mold Advisor to help us control the product and the mold structure in the engineering design phase.

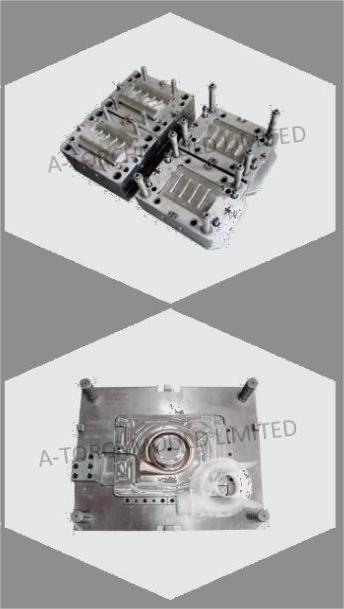

De acordo com a função do produto, estrutura, combinado com os requisitos do cliente, nós vamos escolha razoável moldar o aço e as peças do molde.

Base do molde: DME, HASCO, FUTABA, LKM

Corredor quente: DME, HUSKY, MESTRE-MOLDE, YUDO, HOTSYS, HASCO, SYNVENTIRE

Molde em aço: P20/1,2311、H13/1,2344、718/1.2738、420/1.2316、S136/1.2083、420ß, etc.

Services include:

Frio&Corredor quente, Único&Multi-cavity, Único&Multi-shot, Matrizes de Alumínio Fundido&zinco, Insert Molds, Prototype Tooling, Overmolding, etc.

We have a lot of injection machines in-house, ranging from 80-500 tons. Adequate machines for mould tryout and injection moulding.

We are based on the product features to help customers choose the most suitable raw materials. We also have an obligation to use green and environmentally friendly materials.

Our common plastic materials including ABS, AS, HDPE, LDPE, PA, PC,PE , PMMA, POM, PPS, PVC, TPE, etc. International brands such as DuPont, BAYER, GE/ SABIC etc., are our first choice.

Our molding services include

- Auto Parts

- Precious Industrial Parts

- Medical Parts

- Electronic Parts

- Plastic Toys

- Commodity

- Assembly & Packaging Services

- Outros

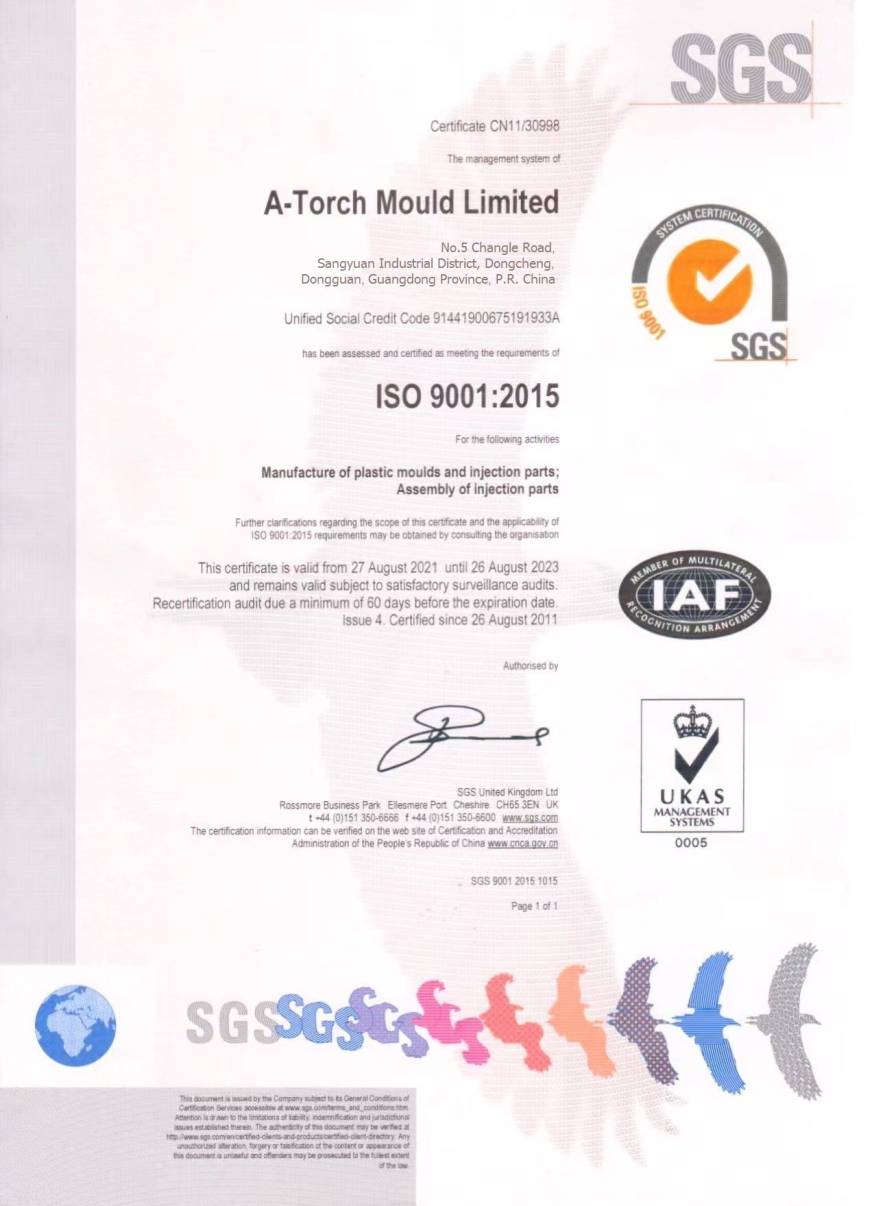

As an ISO certified corperation, we strictly manage and regulate according to ISO9001 quality management system. Together with our QC equipments and experienced quality assurance team we are positioned to provide maximum service, alta qualidade, e entrega no prazo a preços competitivos.

The Certificate of Quality Management System.

We were firstly certified by ISO 9001 in 2008. From then on we always strictly manage and regulate according to ISO 9001 quality management system and benifit from it greatly.

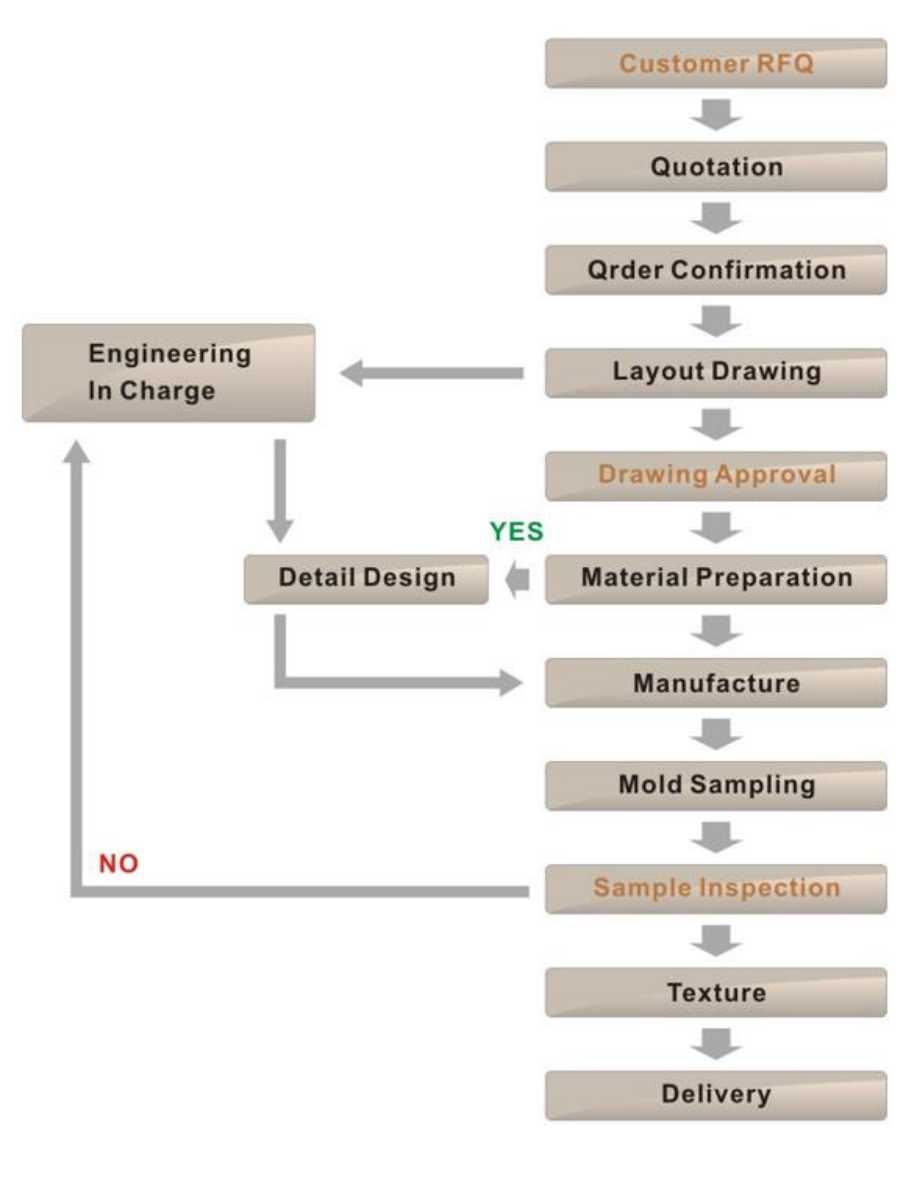

Service Process

We serve the customer from very beginning of RFQ to final delivery. Our sales team will responde to customer actively and effectively

Oversea Exhibition

We atten oversea exhibition regularly every year.

Frankford Mould Show in Germany

Palma Mould Show in Italy

Swiss Exhibition in Swiss

America Mould Show in US

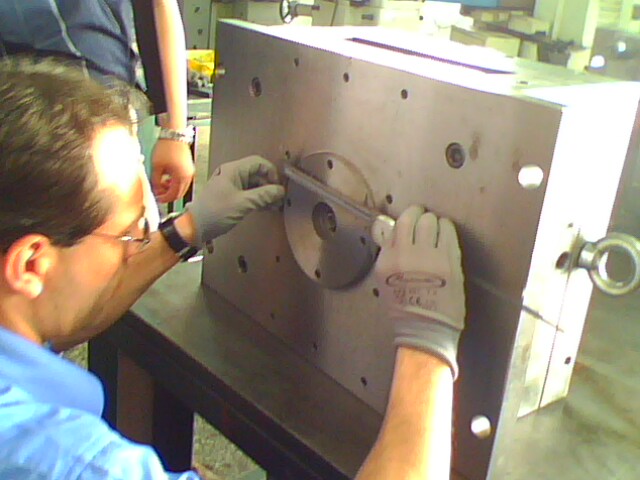

Client Visit

Many of our clients have been to our factory for business development or mould tryout. We also visit our clients regularly every year. These visits deepen our understanding to each other and enhance our relationship.

Our Team

Atualmente, A-TorchMould has lots of senior engineers and professional technicians. Our plenty experiences on mould making will be your reassurance choice for us. We specially recommend our excellent engineers to our new customer. They are professional, responsible, scrupulous, You will save lot of your time and energy when you work with us.

From the original idea to the complete product, we provide full support until your product is finished. Both shifts of our workers are well adapted to the rigorous demands of tight tolerances and short lead-times, whether your need is for prototypes or high volume production tooling.

Clients' Testimonials

We have enjoyed the partnership with A-TorchMould Limited for the past 8 Anos. A-TorchMould Limited is proven to be reliable, dependable and professional. They has producted over 100 moulds for my company and my customers. They are dedicated to quality on-time delivery and competitive pricing. And their engineering deparment offers useful suggestions and recommendations saving us both time and money.

Our cooperation with A-TorchMould Limited started in 2006. A-TorchMould Limited is a very interested and reliable partner. Since then, they have produce for us a considerable number of tools and plastic parts. Cause we are a Swiss company, we pay a lot of attention to quality. A-TorchMould Limited not only understands requirements but also fulfills them. Thus we are very interested to continue working with A-TorchMould Limited in the future.

Get in touch